10 Myths About Aluminum Brazing, Busted

Aluminum brazing is a cornerstone process for industries such as automotive, HVAC, and general manufacturing. Despite its long-standing use and proven reliability, misconceptions about aluminum brazing continue to circulate, often influencing decisions in design, fabrication, and maintenance. These myths range from concerns about strength and durability to misunderstandings about temperature requirements, compatibility with other metals, and the ability to handle complex assemblies. For engineers, fabricators, and maintenance professionals, separating fact from fiction is crucial to maximize performance, efficiency, and safety in their projects.

In this blog, we will discuss some of the most common myths about aluminum brazing, debunk them with clear explanations, and highlight why this process remains a versatile, reliable, and widely trusted solution. From the precision of modern dip brazing techniques to the material's resilience in demanding applications, understanding the realities of aluminum brazing can help teams make informed decisions, reduce errors, and optimize the lifespan and performance of critical components. By examining each misconception and contrasting it with industry facts - including the widespread use and advantages of aluminum in manufacturing - we aim to provide clarity and actionable insights for anyone working with or specifying brazed aluminum components.

Myth 1: "Brazing is just welding with a torch"

Many people assume that aluminum brazing is simply another form of welding. The truth is that brazing and welding are fundamentally different. Welding melts the base metals to form a joint, which can introduce distortion, residual stress, or weaken thin aluminum components. Brazing, by contrast, uses a filler alloy to join parts without melting the base metal. This preserves structural integrity and reduces the risk of warping. Advanced techniques, such as dip brazing or torch brazing, allow technicians to create leak-proof, durable joints even for intricate assemblies, making aluminum brazing an ideal solution for precision applications.

Myth 2: "Brazed joints are weaker than welded joints"

There's a misconception that brazed aluminum joints cannot withstand stress or thermal cycling. In reality, a properly executed brazed joint can handle high mechanical loads, vibration, and repeated temperature changes. This is why brazed aluminum components are widely used in HVAC heat exchangers, automotive radiators, and aerospace assemblies. The key lies in controlling temperature, using the correct filler alloy, and employing precision techniques. Hi-Temp Brazing's skilled technicians ensure joints are both structurally sound and leak-proof, providing reliability across demanding applications.

Myth 3: "Leaks are inevitable in aluminum assemblies"

Many believe that brazed aluminum assemblies will inevitably leak. Modern aluminum brazing methods, however, prevent leaks when performed correctly. Controlled heating, precise filler application, and rigorous quality control ensure joints are sealed tightly. Additionally, advanced leak detection techniques, such as helium testing or pressure testing, can identify potential weak points before assemblies leave the shop. Engineers and fabricators also use design considerations - like proper joint fit and surface preparation - to further minimize the risk of leakage. By proactively addressing these concerns at every stage of production, brazed aluminum components achieve high reliability and long-term performance in both industrial and commercial applications.

Myth 4: "Brazing is slow and energy-intensive"

Some assume aluminum brazing consumes excessive time and energy. In reality, processes like dip brazing allow multiple joints to be completed simultaneously, improving efficiency. This method also minimizes the amount of energy required per assembly. Furthermore, aluminum itself is a highly sustainable material. According to research, recycling aluminum uses over 90% less energy than producing primary aluminum, which makes combining efficient brazing with recycled aluminum both economically and environmentally advantageous. Modern facilities like Hi-Temp Brazing leverage these efficiencies to provide cost-effective, green manufacturing solutions.

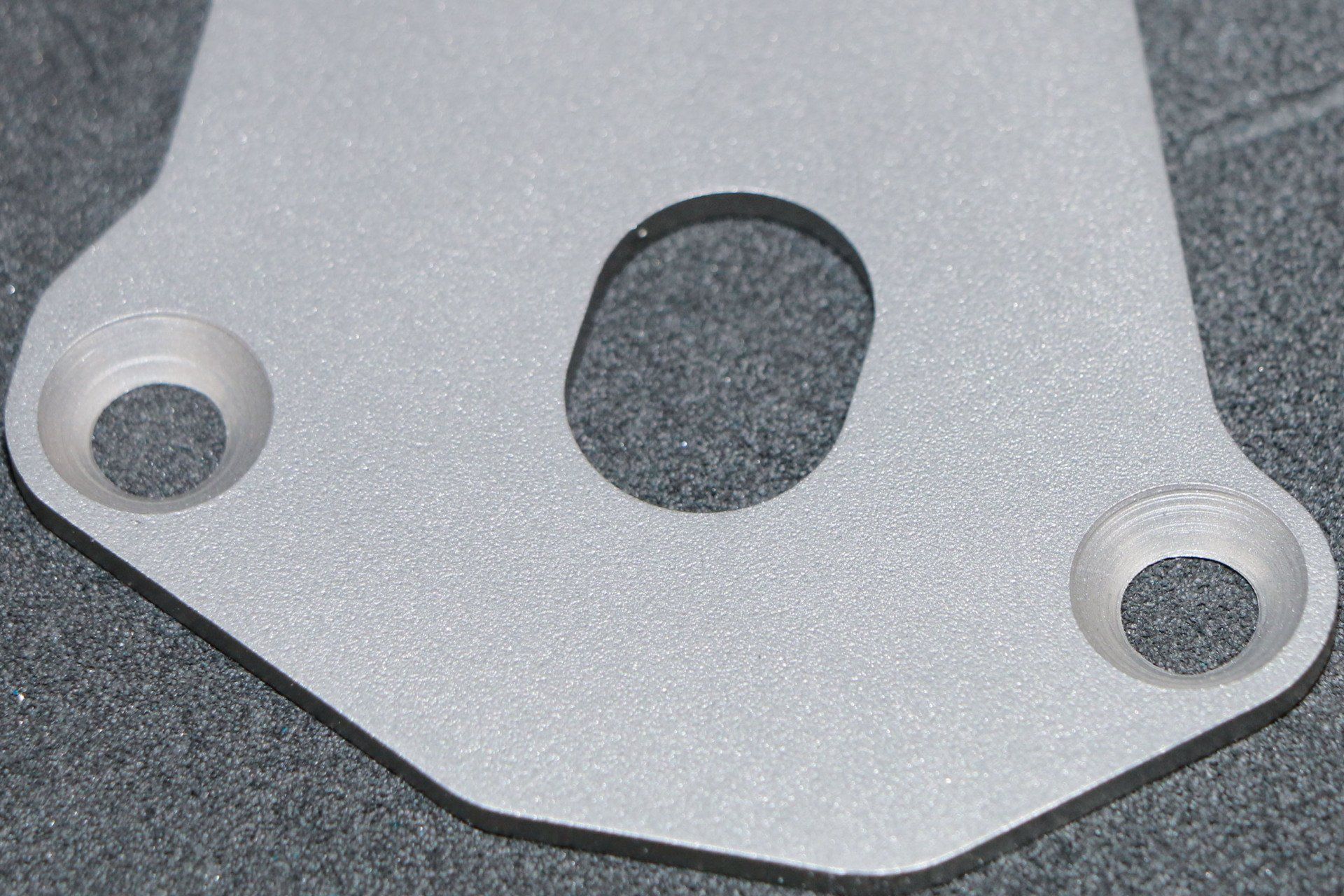

Myth 5: "Brazing is unsafe for intricate aluminum parts"

Many believe aluminum brazing is only suitable for large, simple components. In reality, with precise temperature control and experienced technicians, even intricate assemblies can be brazed safely. The filler material flows evenly into tight joints without deforming delicate geometries, while the base metal retains its strength. Advanced methods like dip brazing provide uniform heating and penetration, enabling connections that would be challenging or impossible with traditional welding. This makes aluminum brazing ideal for both complex industrial components and precision assemblies.

Myth 6: "Aluminum brazing isn't suitable for industrial-grade applications"

A common misunderstanding is that aluminum brazing is only useful for light-duty projects. The truth is that brazed aluminum assemblies meet stringent industrial standards for strength, durability, and leak resistance. Components made with modern brazing techniques are used in critical applications like automotive condensers, heat exchangers, and precision mechanical assemblies. High-quality brazed joints meet or exceed performance expectations, proving that aluminum brazing is as robust as other joining methods while offering additional advantages in thermal efficiency and corrosion resistance.

Myth 7: "Brazing damages the aluminum"

Some fear that exposing aluminum to high temperatures will compromise the material. In fact, aluminum's high thermal conductivity allows heat to distribute evenly, reducing hotspots and preserving the base metal. Proper filler alloys melt at lower temperatures than the base material, preventing structural damage. This makes aluminum brazing particularly suitable for assemblies that must maintain precise tolerances, such as automotive components and HVAC systems.

Myth 8: "Recycled aluminum isn't suitable for brazing"

A misconception is that recycled aluminum lacks the quality necessary for high-performance brazed joints. On the contrary, recycled aluminum retains the same chemical and mechanical properties as primary aluminum. Modern processing ensures that impurities are removed, and alloys are carefully controlled. Using recycled aluminum for brazing not only meets industrial requirements but also reduces environmental impact. By integrating recycled aluminum, manufacturers decrease energy consumption, reduce greenhouse gas emissions, and contribute to a circular economy - an increasingly important factor for sustainable production.

Myth 9: "Brazing is outdated technology"

Finally, some assume aluminum brazing is an old-fashioned or obsolete process. In reality, the field continues to advance with innovations like controlled dip brazing, improved filler alloys, and state-of-the-art leak detection systems. These improvements have increased efficiency, reliability, and environmental performance. Far from being outdated, aluminum brazing remains essential in industries where precision, durability, and leak-proof connections are critical.

Myth 10: "Brazing is only for metallic assemblies"

Some believe that aluminum brazing can only join solid metal parts. While the majority of applications involve metallic components, brazing can also be used to attach aluminum to other metals in dissimilar-metal assemblies, thanks to specialized filler alloys. This capability expands the applications of aluminum brazing into hybrid systems, allowing engineers to design complex assemblies that combine different materials while maintaining strength and corrosion resistance.

Aluminum brazing is a precise, durable, and efficient process that continues to evolve to meet modern industrial demands. From preserving structural integrity to enabling leak-proof, high-performance joints, brazing is far more capable than many myths suggest. Its versatility allows for joining components of varying complexity, thickness, and geometry, all while maintaining the base metal's strength and functionality. When executed by experienced professionals, it ensures superior quality, reliability, and efficiency across automotive, HVAC, and industrial applications.

For businesses and engineers seeking expert aluminum brazing services, Hi-Temp Brazing Inc provides industry-leading solutions, including dip brazing, torch brazing, and advanced leak detection. Our skilled team ensures that even complex aluminum assemblies are completed with precision and care, minimizing the risk of defects or material fatigue. By combining experience, advanced technology, and rigorous quality control, Hi-Temp Brazing Inc delivers reliable, high-performance results that meet the toughest industrial standards, while also supporting sustainable practices through the use of recycled aluminum and energy-efficient processes. This commitment ensures that clients receive both durable and environmentally responsible solutions for their critical manufacturing needs.

Share On: