4 Industries That Benefit From Aluminum Brazing

Aluminum brazing is an innovative process that connects two aluminum parts. This is accomplished using a filler metal that has a lower melting point than the base. It's no secret that aluminum is used all over the country. It's estimated that the total import volume of aluminum for consumption in 2021 increased by 15% compared to that of 2020, according to a United States Geological Survey. Aluminum is a key element in several different processes and systems. Let's look at a few industries that benefit from aluminum brazing.

1. The Aerospace Industry

The brazing process is commonly used in the world of aerospace parts and systems. This industry uses brazing for high-temperature alloys that are used in turbine engines as well as conductive materials that can be used in avionics. It can also be used in pins in turbine castings.

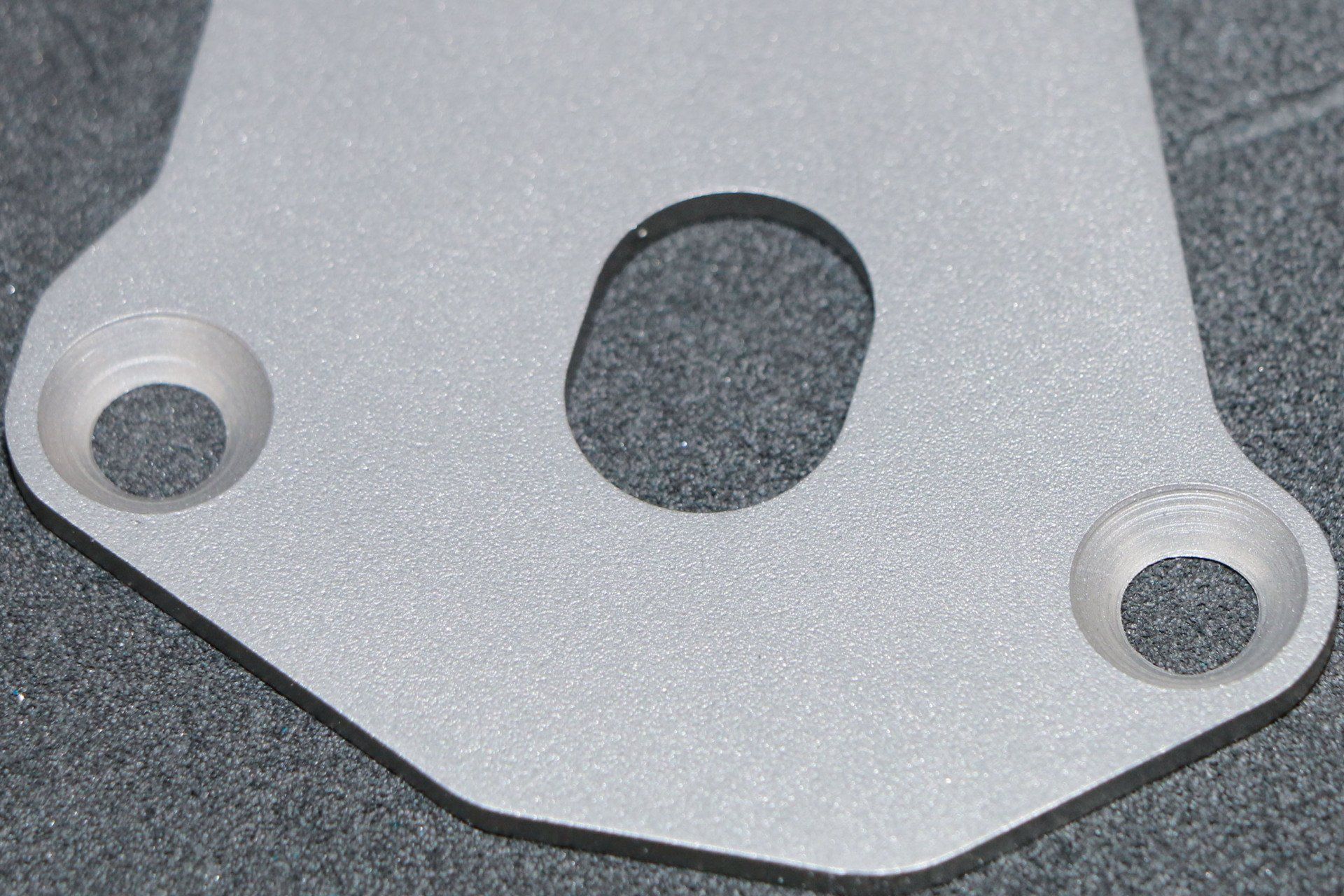

2. The Automotive Industry

This kind of brazing can also be used in the automotive industry. It's used for joining most ferrous and non-ferrous metal components. It's essential that high-purity metals are used in wide-gap brazing, so this method is often necessary to keep automotive manufacturing quality as high as possible.

3. The Tool Manufacturing Industry

Cutting tools require a high level of strength and durability. When components need to be joined, aluminum brazing can be used. This method is especially useful on tungsten carbide-tipped tools. These types of tools often need braze alloy to attach the tip to the steel tool body. This is necessary to increase the rigidity and sharpness. Brazing can also be used to improve downhole cutting and drilling bits.

4. The Medical Industry

Within the medical industry, brazing is also incredibly helpful. There are many medical components, devices, and pieces of equipment that require brazing to ensure durability. Many different types of medical devices require high-purity precious metals. You'll find this in catheters, pacemakers, and neuromodulation devices as well as imaging devices.

These are just a few of the most popular uses for brazing techniques. No matter what industry you're in, it's critical to choose an experienced business for your brazing needs. Here at Hi-Temp Brazing Inc, we've been providing the Deer Park, NY area with quality brazing services for over 45 years. If you'd like to learn more about this process, contact our friendly team today. We look forward to serving you.

Share On: