What Is Aluminum Dip Brazing?

Aluminum dip brazing is considered to be the best form of aluminum brazing because it often has better and more efficient results than other methods. The components of aluminum dip brazing consist of around 88% aluminum and 12% silicon, which provides very strong joints. It's not only effective, but it's inexpensive too. According to the U.S. Geological Survey, the total imports of aluminum for consumption and manufacturing in 2021 alone increased by 15% when compared to previous years. Aluminum dip brazing is clearly winning in the industry. Here is some more information about this effective and inexpensive process that can help increase your production rate while maintaining a high-quality product.

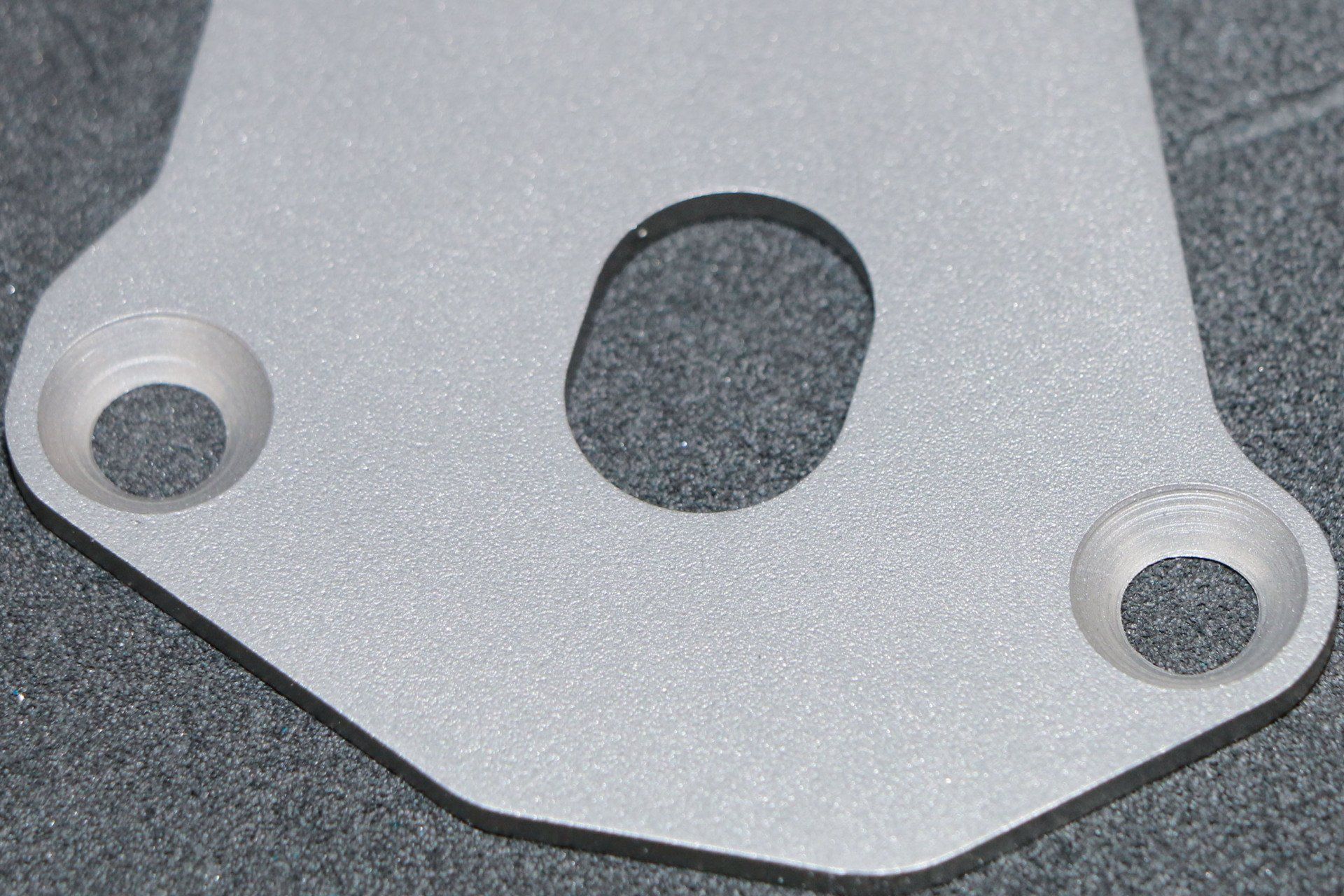

Examples of Aluminum Dip Brazing

There are dozens of examples of aluminum dip brazing being used in manufacturing to help improve the quality of the product. Some of these products include x-rays, various medical equipment, avionics housing, and more. The importance of these items cannot be overstated, and the amount of quality manufacturing that goes into them is even more important to make sure their function is optimal at all times. The parts that are cleaned during this process prevent oxidization, which can taint the quality of the product during its manufacturing phase. By using aluminum dip brazing, the joints are airtight and no oxygen is able to get inside, which prevents corrosion and other forms of long-term damage.

The Process of Aluminum Dip Brazing

The processing time of aluminum dip brazing can vary depending on the product being manufactured. Normally, the component parts are cleaned prior to being assembled. The short version of the process involves applying filler metal paste to all the joints, preheating the apparatus to 985°F, then the length of the cycle timer will depend on what is being made. The materials are then removed from the preheated furnace and placed in a salt bath that is at 1100°F. The item is then moved to a quenching area where it is allowed to cool off. After some cleaning maintenance, the item is hardened at 350°F for around 8 to 10 hours.

If you need professional aluminum dip brazing, High-Temp Brazing Inc is here to help you. We have been providing professional casting services for years and have the expertise to help you. Simply inquire about our services and our team of professionals will be ready to assist at your convenience.

Share On: